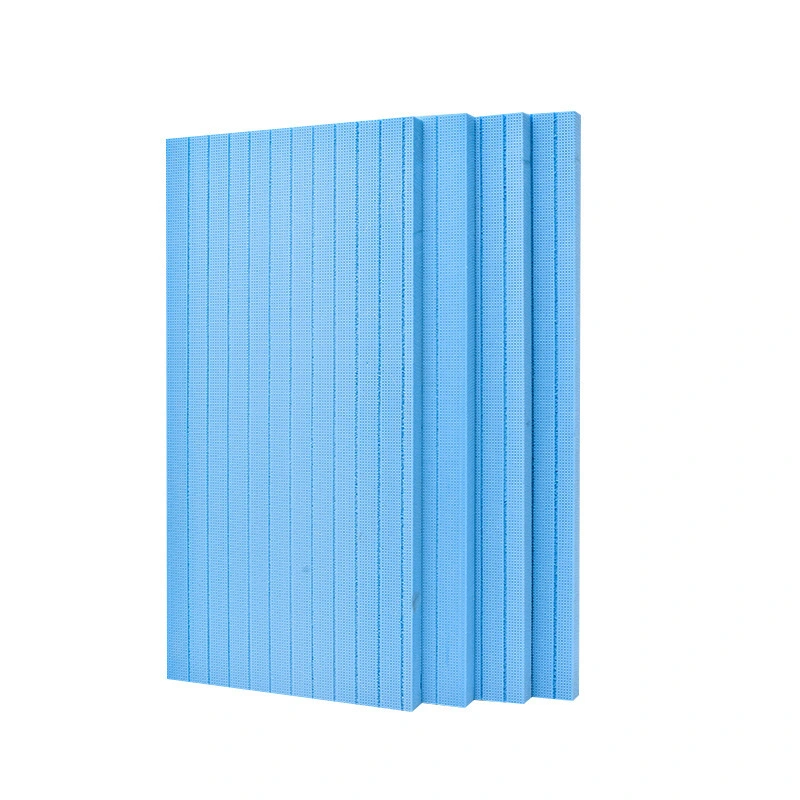

Thermal Insulation 60mm XPS Foam core for building panels RV Truck

Place of Origin: Chongqing, China

Brand name: FR

Model: FR3-003

MOQ: 300 ㎡

Factory Price: Negotiate

Payment Term: T/T,L/C,Paypal,Western Union

Delivery time: air shipping about 7-15 working days; Sea shipping about 30-60 working days

Start Port: Guangzhou/Shanghai

Density: 30~45 Kg/m³

Thickness: 5-120mm

Color of XPS: customized color MOQ

Strength: 170-500KPa

Function: thermal Insulation

Technology: Extrusion

Shape: Flexible

Process: cutting

Application: RV, truck, building panels

product feature

XPS core is a kind of insulation material with polystyrene resin as the main component XPS core, the full name of Extruded Polystyrene, that is, extruded polystyrene, is a closed-cell foam board made by a special process. It is made of polystyrene resin as the main raw material, and then added to other chemical materials, which has excellent thermal insulation performance, high strength and durability.

The XPS core manufacturing process involves heating and mixing polystyrene resin and other raw and auxiliary materials, and then extrusion molding into rigid foam sheets. This material has a perfect closed-cell honeycomb structure, which makes the XPS board have extremely low water absorption, pressure resistance, aging resistance and other characteristics. Due to its many pores on the surface, XPS cores perform well in thermal insulation, thermal insulation and sound insulation, and almost do not absorb water and have strong resistance to aging, so they are very suitable for exterior wall construction and other thermal insulation projects.

Contact Us

Contact: Connie Cao

Phone: 86 15825903604

Email: cqfanrui@fullrangecomposite.com

WhatsApp:15825903604

Address: No.5, Jinfu Sixth branch road, Gunan street, Qijiang district, Chongqing, China