Brand's Key Maintenance for Polyurethane Sandwich Panels

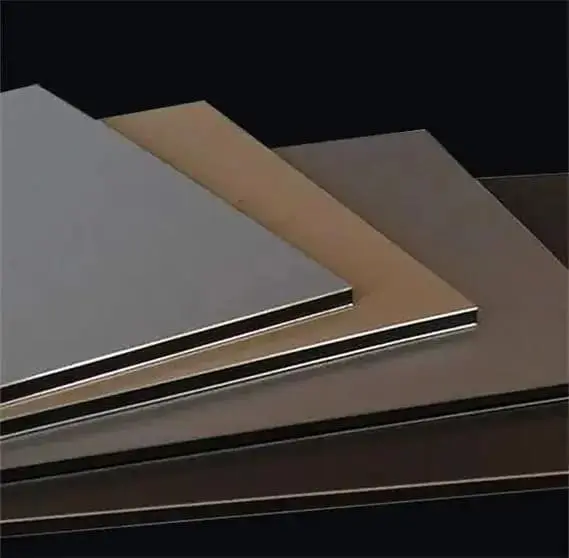

Polyurethane sandwich panels are composite structures made of two polyurethane skins separated by a lightweight core, often made of polyethylene or polystyrene. This sandwich construction provides a balance of strength, insulation, and lightweight properties, making them ideal for a wide range of applications. The panels are known for their excellent fire resistance, low thermal conductivity, and durability, which makes them a great choice for architects and builders.

Despite their many advantages, polyurethane sandwich panels are not immune to degradation over time. Factors such as environmental conditions, UV exposure, moisture, and improper maintenance can compromise their structural integrity and performance. Therefore, regular maintenance is essential to extend their lifespan and prevent costly repairs.

Benefits and Challenges of Using Polyurethane Sandwich Panels

The benefits of using polyurethane sandwich panels are numerous. Their lightweight nature reduces the load on buildings, making them ideal for high-rise structures and sports facilities. Their exceptional insulation properties make them a great choice for energy efficiency, particularly in the construction of buildings in colder climates. Additionally, polyurethane sandwich panels are fire-resistant and have low thermal conductivity, which enhances safety in case of emergencies.

However, there are challenges associated with their use. One of the primary concerns is the potential for water infiltration, which can lead to mold growth and panel degradation. Another challenge is the susceptibility of these panels to UV radiation, which can cause premature aging and cracking over time. Furthermore, proper installation and maintenance are crucial to ensure optimal performance, as improper handling can lead to delamination or buckling.

Maintenance Tips for Polyurethane Sandwich Panels

Effective maintenance of polyurethane sandwich panels requires a proactive approach. Here are some practical tips to ensure the longevity and efficiency of these panels:

- Regular Inspections: Conduct routine inspections every 6-12 months to check for signs of wear and tear, such as cracks, delamination, or discoloration. Early detection of issues can prevent serious damage and reduce the likelihood of costly repairs.

- Proper Cleaning: Use a mild detergent and a soft cloth or sponge to clean the panels. Avoid harsh chemicals and abrasive materials that can damage the surface. For stubborn dirt, use a pressure washer at low pressure (around 1,000 psi) and a mild detergent.

- Insulation Maintenance: Proper insulation is crucial for the energy efficiency of polyurethane panels. Ensure that the panels are insulated on both sides and that no insulation gaps exist, which can lead to heat loss and increased energy consumption.

- Addressing Water Infiltration: Install a drainage system to prevent water accumulation. Seal any gaps around panels to ensure they are protected from the elements. Consider using waterproof sealants or coatings to enhance water resistance.

- Adequate Lubrication: Polyurethane panels are made from polymerized materials, which can become brittle over time. Apply a thin layer of protective coating or lubricant to maintain their flexibility and prevent cracking. Look for products specifically designed for polyurethane panels.

- Regular Trimming: Trim any overhanging edges to prevent tripping hazards and ensure that the panels are aligned properly. This can also help reduce the risk of water infiltration.

By following these maintenance tips, you can extend the lifespan of polyurethane sandwich panels and ensure that they meet their full potential.

Environmental Factors Affecting Polyurethane Sandwich Panels

Environmental factors play a significant role in the lifespan and performance of polyurethane sandwich panels. Exposure to extreme temperatures, moisture, and UV radiation can accelerate degradation and compromise the integrity of the panels. Here are some key environmental factors to consider:

- Temperature Fluctuations: Rapid changes in temperature can affect the polymerization process of polyurethane panels, leading to stress cracks and delamination. Ensure that panels are installed in a stable environment with gradual temperature changes.

- Moisture Exposure: High humidity and moisture can lead to water infiltration, mold growth, and panel degradation. Proper ventilation and drainage systems are essential to prevent moisture buildup. Install moisture barriers and seal any gaps to protect the panels.

- UV Radiation: UV radiation can cause the panels to age prematurely, leading to cracking, crazing, and loss of color. Protect the panels from direct sunlight by using shades or overlying them with reflective coatings. Consider using UV-resistant paint or coatings.

- Exposure to Solvents and Chemicals: Exposure to solvents, cleaning agents, and other chemicals can damage the panels' surface and compromise their insulation properties. Always follow manufacturer guidelines for cleaning and treating panels.

Consistent Maintenance for Optimal Performance

Consistent maintenance is key to ensuring the optimal performance and longevity of polyurethane sandwich panels. Just as the care required for a newly installed panel, consistent maintenance prevents wear and tear, protects the panels from environmental damage, and ensures that they meet their full potential.

- Routine Inspections: Schedule regular inspections every 6-12 months to check for any signs of damage or wear. This can be done on a monthly or quarterly basis, depending on the panel's application and usage.

- Pressure Washing: Periodically clean the panels using a pressure washer to remove dirt, grime, and residues. Be cautious not to over-clean, as excessive pressure can damage the panels' surface. Use a low pressure (around 1,000 psi) and a mild detergent.

- Re-insulation: Re-insulate the panels as needed to maintain their energy efficiency. This can be done by sealing any gaps or cracks that may have developed over time. Use high-quality insulating materials to ensure optimal performance.

- Lubrication and Coatings: Apply a thin layer of protective coating or lubricant to maintain the panels' flexibility and prevent cracking. Consider using reflective coatings to enhance energy efficiency. Follow manufacturer recommendations for application and maintenance.

- Professional Maintenance: In some cases, hiring a professional maintenance service may be necessary to ensure that the panels are maintained to the highest standards. A qualified technician can identify potential issues and apply the appropriate treatments.

By adopting a consistent maintenance routine, you can ensure that polyurethane sandwich panels remain in optimal condition and deliver their full potential.

Real-World Challenges in Maintaining Polyurethane Sandwich Panels

Maintaining polyurethane sandwich panels can present a range of challenges, particularly in real-world settings. Here are some of the most common challenges:

- Accessibility: In some cases, the panels may be installed in hard-to-reach locations, such as high-rise buildings or outdoor structures. This can make regular inspections and maintenance difficult and time-consuming.

- Labor-Intensive Tasks: Maintaining polyurethane panels often requires specialized tools and equipment, as well as a good deal of manual labor. This can be a barrier for small businesses or homeowners who lack the resources or expertise to perform the tasks themselves.

- Cost: The cost of maintaining polyurethane panels can be a significant expense, particularly for large-scale projects or facilities with a high number of panels. However, investing in proper maintenance can save money in the long run by preventing costly repairs and extending the panels' lifespan.

- Regulations and Standards: Adhering to environmental regulations and safety standards can be a challenge, particularly when it comes to handling chemicals and performing certain types of inspections. Ensuring compliance with these regulations can add to the complexity and cost of maintenance.

Conclusion

Polyurethane sandwich panels are a versatile and durable material with a wide range of applications in construction and design. Their growing popularity is driven by their lightweight nature, fire resistance, and energy efficiency. However, like any material, they require proper maintenance to ensure their longevity and efficiency. By understanding the benefits and challenges of using polyurethane panels, adopting effective maintenance practices, and addressing environmental factors, you can maximize their performance and extend their lifespan.

Regular inspections, proper cleaning, and timely repairs are essential to maintaining the structural integrity and performance of polyurethane sandwich panels. Additionally, leveraging protective measures such as insulation, lubrication, and reflective coatings can further enhance their performance and longevity. Consistent and proactive maintenance is not just a precautionary measure; it is a critical component of their overall efficiency and effectiveness.

In conclusion, maintaining polyurethane sandwich panels is not just about preventing damage; its a smart investment in the future of your building's performance and sustainability. By taking the necessary steps to care for these panels, you can ensure they continue to provide exceptional value and longevity for years to come.

Contact Us

Contact: Connie Cao

Phone: 86 15825903604

Email: cqfanrui@fullrangecomposite.com

WhatsApp:15825903604

Address: No.5, Jinfu Sixth branch road, Gunan street, Qijiang district, Chongqing, China