Difference between Plastic Honeycomb Composite Panels and Traditional Materials

Plastic honeycomb composite panels offer numerous advantages in architectural design, making them a significant improvement over traditional materials. These panels are incredibly lightweight, reducing overall building weight, which significantly lowers foundation costs and eases transportation. This reduces environmental impact and construction timelines, contributing to more sustainable and cost-effective construction projects. Additionally, they exhibit exceptional durability, providing excellent resistance to wear and tear, thus extending the lifespan of buildings and reducing the need for frequent maintenance and repairs. Their superior acoustic performance is another notable advantage, thanks to the honeycomb structure that provides superior sound insulation, creating quieter indoor environments and enhancing occupant comfort. Furthermore, their high thermal insulation properties help maintain optimal indoor temperatures, leading to reduced energy consumption for heating and cooling. Lastly, they are cost-effective, with lower material and shipping costs coupled with the ability to use lighter structures, contributing to significant long-term financial savings.

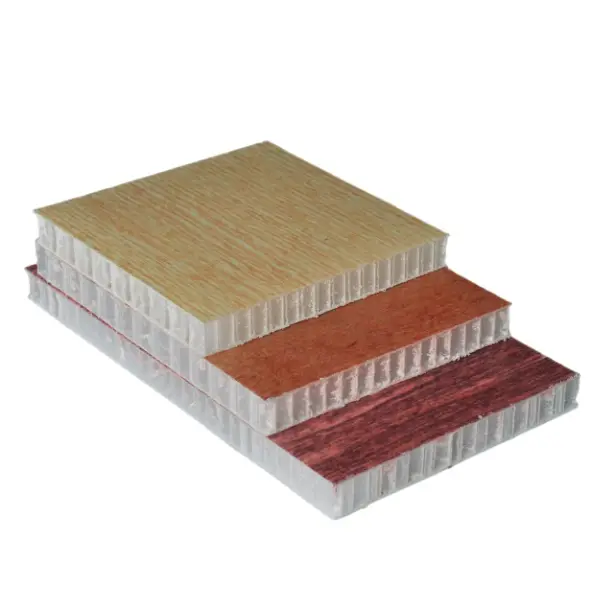

Strength and Weight Properties of Plastic Honeycomb Panels

Plastic honeycomb composite panels have emerged as a superior choice due to their exceptional strength-to-weight ratio, making them particularly advantageous in applications where lightweight durability is critical, such as in aerospace, automotive, and construction. Their advanced manufacturing processes, which involve the use of high-strength polymers and optimized cell structures, significantly enhance their mechanical properties, making them competitive against traditional materials like aluminum and steel. For instance, in aerospace, these panels reduce weight without compromising on structural integrity, contributing to improved fuel efficiency and reduced emissions. Similarly, in the automotive industry, they achieve substantial weight savings and enhanced safety. The panels' performance is further enhanced by their potential integration with smart building technologies, which optimize energy efficiency and maintenance costs. Additionally, their recyclability and low environmental impact make them a compelling option for sustainable design and construction projects.

Applications of Plastic Honeycomb Composite Panels in Modern Design

Plastic honeycomb composite panels are increasingly preferred in modern design due to their lightweight and high-strength properties, enabling the creation of complex and innovative forms. These panels enhance both the aesthetic and structural integrity of buildings, providing superior thermal insulation and energy efficiency, which align with sustainable building practices. For instance, notable projects such as the Bullitt Center in Seattle have successfully utilized plastic honeycomb composites for their exterior walls and roof, achieving net-zero energy status. Internally, these panels are used for modular partitions and ceiling systems, optimizing acoustic performance and thermal comfort. The unique design flexibility of plastic honeycomb composites allows for the creation of complex, organic shapes and curved surfaces, making them ideal for modern structures that demand both functionality and visual impact. By integrating smart technologies, these panels further enhance their utility, enabling the generation of renewable energy and creating responsive building environments.

Benefits of Plastic Honeycomb Panels in Construction

Plastic honeycomb panels offer numerous benefits in construction, including their lightweight design, which reduces the load on buildings, making transportation and installation easier and faster, thus lowering costs and minimizing environmental impact. They also enhance thermal and moisture resistance, improving energy efficiency and prolonging the lifespan of structures, which reduces maintenance and energy bills. Their high strength-to-weight ratio ensures robust support while maintaining minimal thickness, ensuring structural integrity without adding excessive bulk. These panels are durable and long-lasting, resistant to weathering, UV radiation, and wear and tear, offering consistent performance over time. Additionally, they are often manufactured from recycled materials and feature energy-efficient production processes, aligning with green building practices.

Comparison of Plastic Honeycomb Composite Panels with Other Materials

Plastic honeycomb composite panels stand out in comparison to other materials due to their unique properties and applications. They are significantly lighter than traditional materials like aluminum (20-40% lighter) and steel (up to 90% lighter), making them ideal for transport and installation. Their high stiffness-to-weight ratio surpasses wood, offering better resistance to moisture and degradation. In contrast, aluminum is known for its high strength and durability but is heavier and more expensive than plastic honeycomb panels. Steel, while durable and strong, is much heavier and requires more energy in production, making it less environmentally friendly. Wood, though cost-effective and aesthetically pleasing, is heavier, less durable, and more susceptible to moisture and degradation. Glass fiber offers high tensile strength and durability but is heavier than plastic honeycomb panels and more difficult to shape for complex designs.

Advantages of Plastic Honeycomb Composite Panels

Plastic honeycomb composite panels provide several key advantages, including remarkable structural efficiency, lightweight design, exceptional thermal insulation, recycling potential, and cost-benefit analysis. These panels offer remarkable strength-to-weight ratios, enabling the design of lightweight yet robust structures, enhancing durability while reducing material usage and associated costs. Their lightweight design contributes to minimal material weight, which is particularly advantageous in applications requiring reduced load-bearing capacities or where lightweighting is critical for balance and maneuverability. Their superior thermal insulation properties significantly reduce heat transfer, leading to lower energy consumption for heating or cooling and a more comfortable indoor environment. Although recycling techniques for plastic honeycomb panels are still being developed, they offer promising potential for more sustainable disposal and reuse. A cost-benefit analysis reveals that, while initial investment costs can be higher, long-term savings are realized through reduced maintenance and operational expenses, making them a fiscally sound choice for many projects.

Environmental Impact of Plastic Honeycomb Panels vs. Traditional Building Materials

Exploring the environmental impact of plastic honeycomb panels and traditional building materials reveals a complex landscape of benefits and challenges. In terms of material production, plastic honeycomb panels often have lower greenhouse gas emissions due to their lightweight nature, although traditional materials like concrete and wood have higher emissions but offer carbon sequestration benefits. Energy consumption is another critical aspect, where plastic honeycomb panels typically require less during manufacturing and transportation, while traditional materials like wood and concrete maintain their advantages with superior energy-efficiency in construction and insulation. Lifecycle assessments show that plastic honeycomb panels emit fewer greenhouse gases during production, although traditional materials emit more due to energy-intensive processes such as cement production. Resource utilization is also a key consideration, with traditional building materials often requiring more significant amounts of raw materials. End-of-life management of plastic honeycomb panels remains challenging, with many ending up in landfills, but innovations in recycling, such as upcycling into new construction materials and converting waste into road aggregate, are gradually improving the sustainability of these panels.

Contact Us

Contact: Connie Cao

Phone: 86 15825903604

Email: cqfanrui@fullrangecomposite.com

WhatsApp:15825903604

Address: No.5, Jinfu Sixth branch road, Gunan street, Qijiang district, Chongqing, China